With H. Loeb, when you need a part, you also get a partner.

H. Loeb Corporation teams with our customers to provide engineering solutions to the toughest problems. Whether choosing the right material, designing a particular part, or improving the quality of your product, our engineers will work with you to turn your concept, drawing or upgrade into reality. In doing so, one of the most important steps in the process is in prototyping.

From Idea to Prototype

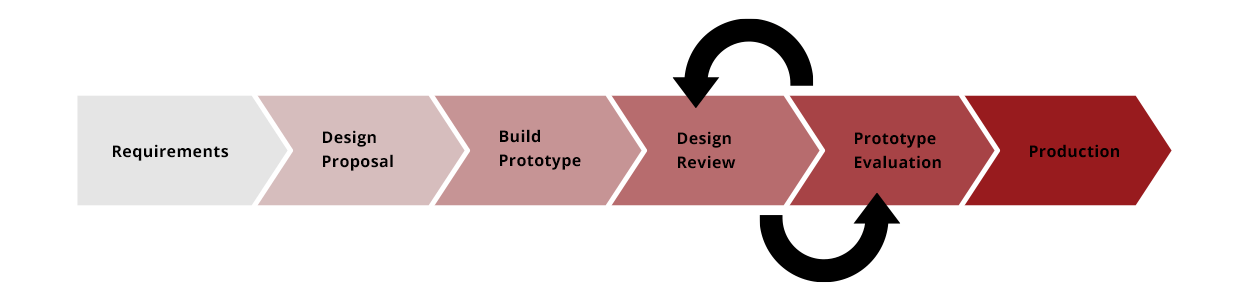

Prototyping plays a vital role in any product’s development. It is a result of a process that begins with an initial inquiry from a customer and ends with a functioning product ready for a full-scale production run. In some instances, pending material availability, a 24-hour turnaround is possible to complete a prototype.

Why is Prototyping Important?

Prototypes provide sample products that allow mechanical engineers and designers to visually assess, test, validate and evaluate the product through each stage of its advancement. By building a sample, model, or draft version of a product any preliminary changes, alterations or fixes can occur before full-scale production begins.

Custom Product Prototype Services

Prototyping a product allows for great flexibility during the design phase, too. There is no rush or need to tool-up for production when prototyping. In fact, product designs normally undergo a number of prototyping processes before they are ready for production. There is no need to commit to a design until you are satisfied.

At H. Loeb Corporation, we recognize prototypes as an essential part of your product development process. We work with our customers throughout the process— no matter how challenging the product or part may be. When there is no standard answer, we custom problem-solve with you to come up with the end prototype to successfully bring your product to market.